Table of Contents

When designing or maintaining an industrial system, choosing the right instrumentation cables is critical to ensuring proper functionality and long-term reliability. Instrumentation cables, such as screened instrumentation cables, industrial instrumentation cables and copper instrumentation cables, are essential for transmitting signals in a variety of control and monitoring applications. The decision on which type of cable to select depends on several factors that can affect the performance, durability and overall safety of the system. This article outlines the key factors that must be considered when selecting instrumentation signal cables for any application.

Understanding the Types of Instrumentation Cables

Before diving into the selection process, it’s important to understand the different types of instrumentation cables available on the market. The two most common categories include:

- Unscreened Instrumentation Cables: These cables are typically used in environments with minimal electrical noise interference. They are simpler in construction and are often more cost-effective but may not offer the same level of protection as their screened counterparts.

- Screened Instrumentation Cables: These cables are equipped with shielding to protect the signal from external interference, making them ideal for environments with high electromagnetic interference (EMI) or radio frequency interference (RFI). Screened cables are particularly important in industrial settings where the integrity of signal transmission is critical.

- Industrial Instrumentation Cables: These cables are designed specifically for industrial environments. They may include additional layers of insulation, shielding and armor to protect them from physical damage and environmental factors like moisture, chemicals and high temperatures.

- Copper Instrumentation Cables: Copper cables are widely used for their excellent electrical conductivity, making them ideal for applications that require high-performance signal transmission. They are often used in both unscreened and screened configurations.

Selecting Industrial Instrumentation Cables: Environmental Conditions

Testimonials

Guys it’s really good quality of cables…..

I am also using. So why are you wating🧐

Order Now………

The environmental conditions of the installation site are one of the most important factors to consider. The cable should be capable of withstanding the specific environmental factors it will encounter, including:

- Temperature: Instrumentation cables should be selected based on the temperature range in which they will operate. If the cables will be exposed to extreme temperatures, either high or low, it’s essential to choose cables that are rated for those conditions to ensure their longevity and performance.

- Moisture and Chemicals: If the cables are installed in areas with high humidity or exposure to chemicals, it’s important to select cables with proper insulation and protection. For instance, PVC (polyvinyl chloride) or thermoplastic elastomer (TPE) are common materials used to provide moisture and chemical resistance.

- Physical Damage: In industrial environments, instrumentation cables may be exposed to physical damage, including abrasion, impact or crushing. Cables with additional armor or protective layers, such as steel wire braiding or metallic sheathing, may be necessary for added protection.

Choosing the Right Copper Instrumentation Cables: Cable Construction and Insulation Materials

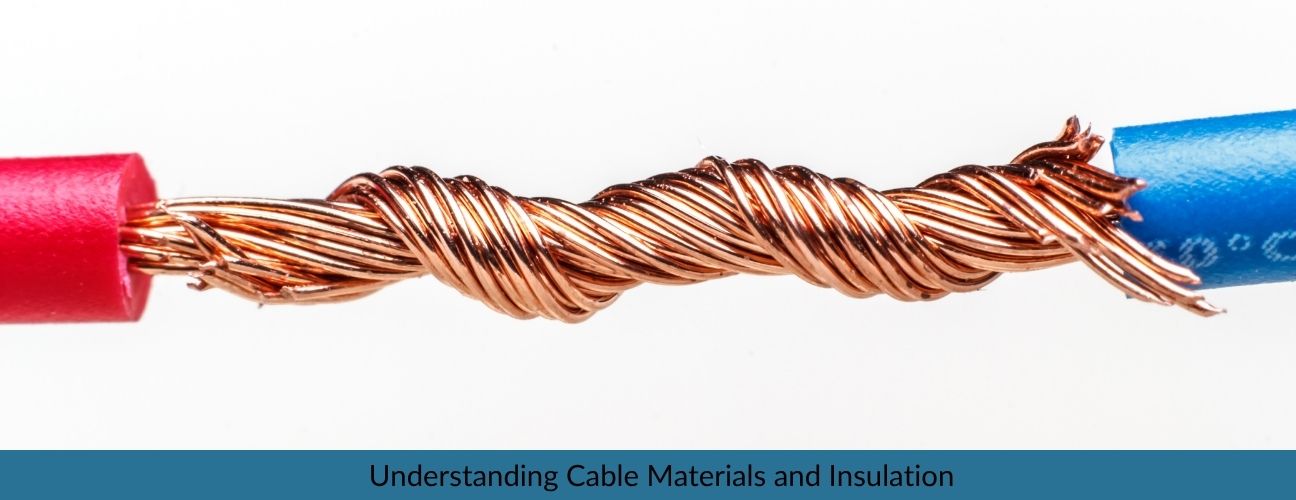

The construction and insulation materials used in the cable play a significant role in its overall performance and durability. Common materials include:

- PVC (Polyvinyl Chloride): PVC insulation is cost-effective and commonly used in general-purpose applications. It offers moderate resistance to chemicals, moisture and temperature fluctuations.

- XLPE (Cross-Linked Polyethylene): XLPE is used for higher temperature applications due to its superior heat resistance. It’s a common choice for instrumentation cables that need to operate in environments with elevated temperatures.

- LSZH (Low Smoke Zero Halogen): Cables with LSZH insulation are ideal for environments where fire safety is a priority. These cables emit minimal smoke and no halogen gases when exposed to fire, making them suitable for use in confined spaces or places with strict fire safety regulations.

- FEP (Fluorinated Ethylene Propylene): FEP offers excellent resistance to heat, chemicals and UV rays, making it an excellent choice for cables used in harsh environments, such as those in chemical plants or outdoor installations.

Signal Integrity and Noise Suppression: Choosing Screened Instrumentation Cables for Signal Protection

The main function of Instrumentation Cables is to transmit signals accurately and without interference. Therefore, ensuring signal integrity is crucial, especially in environments with high electrical noise. Factors to consider here include:

- Shielding: Screened instrumentation cables often feature a layer of shielding to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). There are different types of shielding, such as foil, braiding or a combination of both. The choice of shielding depends on the level of interference present in the environment and the required signal clarity.

- Twisted Pairs: For environments with particularly high interference, cables with twisted pairs or multiple twisted pairs can help reduce cross-talk and noise. This design minimizes the impact of external noise and ensures that the signals are transmitted more accurately.

- Grounding: Proper grounding of instrumentation cables can significantly improve the effectiveness of noise suppression. A properly grounded cable system reduces the risk of electrical shock and ensures signal clarity by providing a safe path for stray currents to dissipate.

Voltage and Current Rating: Ensuring Compatibility with Industrial Instrumentation Cables

Each type of instrumentation cable has a specific voltage and current rating. When selecting instrumentation cables, it’s important to match the cable’s voltage and current rating with the requirements of the system to prevent overheating, signal degradation or failure.

- Voltage Rating: The voltage rating indicates the maximum voltage the cable can safely handle without breaking down. It’s important to select cables with a voltage rating that exceeds the operating voltage of the system to ensure safety and reliability.

- Current Rating: The current rating refers to the amount of electrical current the cable can carry without excessive heating. When selecting instrumentation cables, it’s essential to ensure that the current rating matches the expected current load in the application.

Cable Length and Signal Loss: Minimizing Attenuation in Instrumentation Signal Cables

The length of the cable run can have a significant effect on signal integrity, especially when long distances are involved. As the length of the cable increases, the signal may experience attenuation or loss, which can affect the accuracy of the data being transmitted.

- Signal Loss: Signal loss occurs due to resistance in the cable and is more pronounced over longer distances. To minimize this, select cables with low resistance and high-quality conductors, such as copper or silver.

- Repeaters and Signal Boosters: In some cases, additional equipment such as repeaters or signal boosters may be necessary for very long cable runs to amplify the signal and reduce loss.

Conclusion

Selecting the right instrumentation cables requires careful consideration of several factors, including environmental conditions, cable construction, shielding requirements and compliance with industry standards. By understanding the specific needs of the application and evaluating the available options, it is possible to choose the most suitable cables to ensure reliable signal transmission, durability and safety. Whether you’re dealing with screened instrumentation cables, copper instrumentation cables or industrial instrumentation cables, taking these factors into account will help ensure optimal performance and longevity of your system.

Table of Contents