Table of Contents

When purchasing electrical wires for residential or industrial applications, Polycab wires are often the go-to choice in India. Known for their durability and high performance, these wires are used extensively across various sectors. The cost of electrical wires depends on several factors that contribute to the final price, ranging from raw materials to market trends. Understanding these key factors can help consumers make informed purchasing decisions, ensuring that they get the best value for their money.

This article discusses the primary factors that influence the price of Polycab wires in India, offering insight into how different elements come together to determine the final cost.

Testimonials

“Guys it’s really good quality of cables…..

I am also using. So why are you wating

Order Now………”

Raw Material Costs

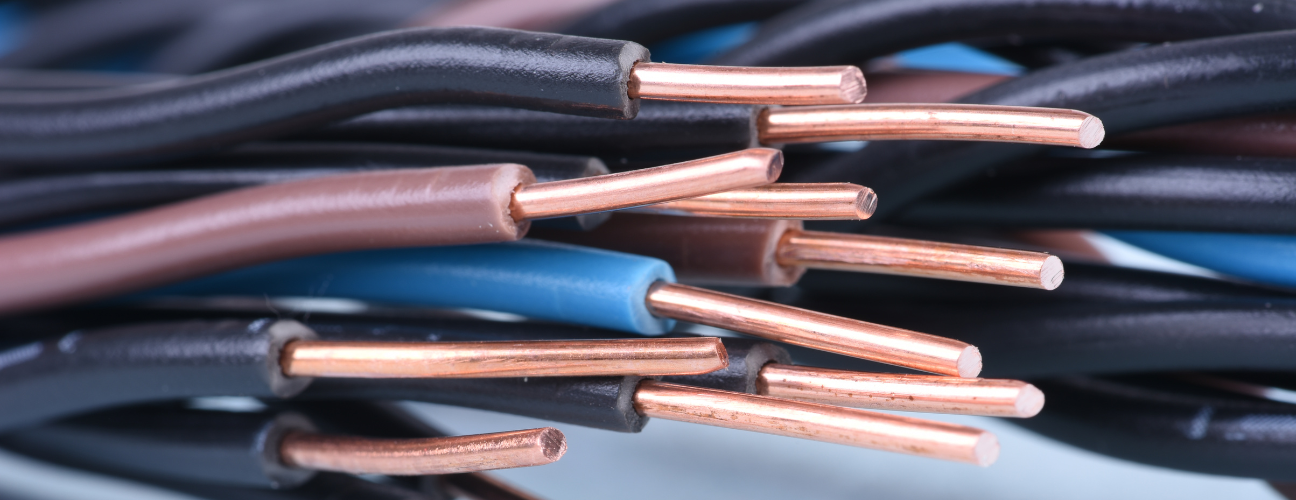

Impact of Copper and Insulation Materials

The cost of raw materials is one of the largest contributors to the overall price of Polycab wires. Wires made from copper conductors are typically more expensive than aluminum wires, primarily because copper is a superior conductor of electricity. Copper prices fluctuate on the global market and these changes have a direct impact on the final price of wires.

In addition to copper, the type of insulation used in the wires also plays a significant role. PVC insulation, commonly used in Polycab’s house wires, is designed to protect the wiring from electrical faults, moisture and external environmental factors. The cost of PVC and other insulation materials also contributes to the overall price of the wire.

Manufacturing and Production Costs

The cost of producing Polycab wires involves several factors that affect the final price. These include the labor costs for manufacturing, the cost of machinery and overhead costs for maintaining production facilities. Additionally, advancements in technology, such as automation and modern manufacturing techniques, may influence production efficiency but can also require significant investment.

- Labor: The workforce involved in manufacturing and quality control directly affects production costs.

- Technology: Up-to-date machinery helps improve wire quality and reduces defects, but the initial cost of machinery can raise prices in the short term.

Brand Reputation and Quality Standards

Polycab’s reputation as a leading wire manufacturer in India significantly impacts the price of its products. The company focuses on delivering high-quality products that meet stringent safety standards. Wires that are flame retardant, highly durable and meet RoHS regulations often come at a premium. The commitment to quality and certifications results in a higher manufacturing cost, which reflects in the price.

- Safety Features: Wires designed for safety, like flame retardant wires, are priced higher due to the added materials and rigorous testing involved.

- Compliance: Certification costs also contribute to higher prices, ensuring that the wires are safe for use in various applications, including industrial and residential setups.

Market Demand and Supply

The pricing of Polycab wires is also influenced by demand and supply dynamics in the market. When demand for electrical wiring increases-due to construction projects, industrial expansion or seasonal fluctuations-prices may rise accordingly. Conversely, when demand drops, prices may decrease.

- Construction and Industrial Demand: With the growth of residential construction, office spaces and industrial projects, the demand for wiring solutions like Polycab house wires also increases, potentially raising prices.

- Seasonal Fluctuations: Prices may fluctuate depending on the season, as more projects are initiated during certain months of the year.

Distribution and Logistics Costs

Transportation and logistics play a critical role in determining the price of Polycab wires. The cost of moving the product from manufacturing plants to retailers or consumers across India can add up, especially if the destination is far from the manufacturing location.

- Transportation Costs: The longer the distance from the production facility, the higher the transportation costs, which may increase the price of the product.

- Storage and Warehousing: The cost of storing large quantities of wires in warehouses and the associated management costs may also be factored into the price.

Competition and Market Pricing

In any competitive market, the pricing strategy adopted by various manufacturers, including Polycab’s competitors, plays a role in determining the final price of Polycab house wires. The presence of competing brands influences the pricing decisions made by distributors and retailers.

- Price Competition: If competitors offer similar quality products at lower prices, it may adjust its prices to remain competitive while maintaining its quality.

- Market Perception: Brand value also plays a role in pricing, as Polycab is known for offering reliable and long-lasting products. This reputation may allow the brand to maintain a higher price point compared to lesser-known competitors.

How Polycab Wire Price is Structured?

Cable Length and Gauge

The length and gauge (thickness) of the wire directly affect its price. Longer cables or those with larger gauges, which require more raw material, are priced higher. For instance, a wire will generally cost less due to the amount of material used and its capability to carry more current.

Wire Type

As mentioned earlier, copper wires are generally more expensive than aluminum wires due to copper’s higher conductivity and durability. However, copper is preferred for most applications due to its superior performance and long lifespan, justifying the higher price.

Specialized Features

Wires designed with flame retardant or UV-resistant features are typically more expensive. These features provide added safety, especially in residential or industrial settings where fire safety is a concern or where wires are exposed to harsh environmental conditions.

Conclusion

Understanding the various factors that influence Polycab wire prices can help consumers make well-informed decisions when purchasing wiring solutions. Whether you are building a new home, renovating an existing property or setting up an industrial facility, the price of Polycab wires is determined by raw material costs, manufacturing processes, market demand and several other considerations. By keeping these factors in mind, you can ensure that you are choosing the right type of wire for your needs, while also staying within your budget.

When considering Polycab house wire prices, remember that investing in high-quality wires is crucial for long-term safety and performance. Polycab’s reputation for quality, safety and durability ensures that their wires are a reliable choice, making them a preferred option for electrical installations in India.

Table of Contents