Table of Contents

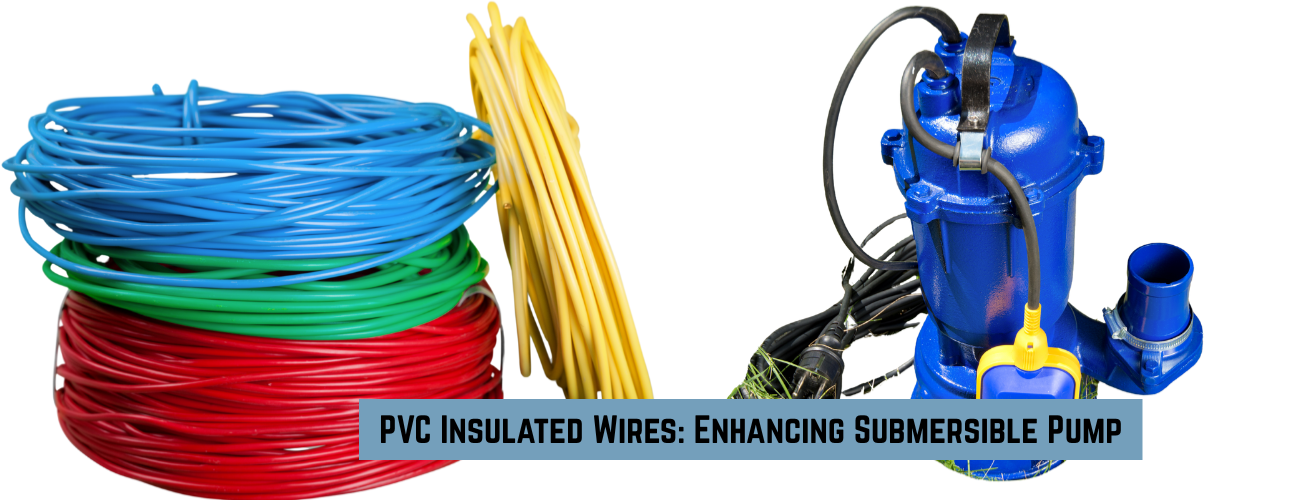

Submersible pump motors are indispensable in water extraction systems, agricultural irrigation, industrial pumping stations and municipal water management. These motors operate in submerged, high-pressure and moisture-intensive environments. The reliability of their internal winding system is essential to ensuring operational longevity and minimal maintenance. At the heart of that system lies a crucial component: PVC insulated winding wires.

Built specifically to endure water immersion, electrical load cycles and harsh mechanical conditions, PVC insulated winding wires form the foundational layer of protection and efficiency within these motors. Whether they’re made from PVC insulated flexible cables, the insulation plays a pivotal role in maintaining structural and operational integrity over time.

Let’s explore how these wires elevate motor performance, ensuring durability, safety and continuous operation.

Understanding the Construction of PVC Insulated Winding Wires

PVC winding wires are typically designed using high-conductivity copper or aluminium conductors, which are then layered with polyvinyl chloride (PVC) insulation. This combination creates a protective shield that defends against moisture penetration, dielectric failure and temperature stress.

The PVC compound used for insulation is not just for electrical isolation – it is specifically formulated to resist hydrolysis, mechanical stress and thermal deformation. These properties are essential when the wires are immersed in water or exposed to hydraulic pressure for long durations. In PVC insulated copper conductor cable, the superior conductivity of copper ensures minimal resistance loss, while PVC insulation maintains the cable’s dielectric strength even in saturated environments.

Additionally, PVC offers good adhesion to the conductor, which prevents delamination during thermal cycles or motor vibration. This stable interface between insulation and conductor ensures reliable operation under fluctuating load and voltage conditions.

Testimonials

“Guys it’s really good quality of cables…..

I am also using. So why are you wating

Order Now………”

Moisture Resistance: Safeguarding Submersible Systems

In a submerged motor, the biggest risk to electrical reliability is moisture ingress. Once water breaches the insulation, corrosion, short circuits and electrical failures become inevitable. PVC insulated winding wires address this with a high level of water resistance, effectively forming a non-porous barrier that blocks water molecules from seeping in.

The insulation in PVC insulated electrical wires undergoes stringent testing to ensure low water absorption and zero capillarity. Even when continuously submerged, the insulation retains its dielectric strength, ensuring safe voltage handling without breakdown. This resistance to hydrostatic pressure extends the service life of the motor, especially in deep well or high-pressure applications.

Moreover, PVC’s chemical inertness protects against contaminants often found in groundwater, such as minerals, salts or mild acids, which may otherwise degrade lesser-quality insulation materials. This added protection is critical in extending motor service life in corrosive and mineral-rich water conditions.

Thermal Performance and Current Handling Capabilities

Temperature control within submersible motors is vital. The confined casing of these motors limits natural heat dissipation. If the insulation material fails to handle high temperatures, it can degrade, melt or crack – compromising motor function.

PVC insulated winding wires, particularly those used in PVC sheathed power cable systems, exhibit excellent thermal properties. Withstanding continuous temperatures, these wires resist deformation under prolonged heating. Additionally, the thermal endurance of PVC ensures that the insulation remains elastic and mechanically strong even after thousands of operational hours.

The conductor – whether aluminium or copper – is selected based on current requirements, but the insulation ensures minimal loss. PVC insulated flexible cables, used in tighter motor windings, accommodate bend radius requirements while maintaining insulation thickness and thermal behavior.

As the winding wires handle current loads efficiently with minimal losses, the result is reduced internal heating and better overall efficiency, which translates to lower energy consumption per unit of water pumped.

Mechanical Strength and Structural Integrity in High-Vibration Applications

Submersible motors face considerable mechanical stress due to fluid turbulence, high-start torque and prolonged operational cycles. PVC insulated winding wires offer excellent mechanical resilience, especially important during installation and dynamic operation.

The PVC insulation used is highly resistant to abrasion and cut-through damage. This allows the winding to maintain its shape and insulation quality during slot insertion and under vibratory loads. When applied as part of PVC insulated winding wires, this robust protection ensures that the wires do not tear, peel or shift over time, preventing conductor exposure.

These wires also resist pressure-induced compression. This is especially relevant in high-depth borewells, where hydrostatic pressure is significant.

The PVC insulated aluminium cable configurations remain dimensionally stable, ensuring a snug, secure coil inside the motor core.

Chemical Stability and Corrosion Resistance

In addition to physical durability, PVC insulated wires offer excellent resistance to a wide range of chemical agents. Borewells and submersible systems often operate in areas with chemically reactive groundwater. Over time, exposure to such elements can degrade standard insulation.

PVC insulation, with its non-reactive properties, protects the internal conductor from corrosion and electrochemical breakdown. This ensures that even in water with varying pH levels, the integrity of the winding wire remains intact.

In some applications, PVC insulated winding wires may also be provided with double insulation or specialized sheathing layers to further enhance chemical resistance. Such variants of PVC insulated electrical wires help extend motor life in applications such as desalination plants, sewage pumps and chemical water extraction systems.

Manufacturing Consistency and Ease of Winding

Another key advantage of using PVC insulated winding wires is their compatibility with high-speed winding equipment. The wires maintain uniform diameter, insulation thickness and surface smoothness – all vital for efficient motor production.

PVC insulated flexible cables allow for tight coiling with reduced spring-back, which enhances packing density without increasing risk of damage. These winding wires are designed for consistent tension during winding, minimizing the chance of overlap, gaps or inconsistencies in slot filling.

In manufacturing environments, this leads to quicker motor assembly times and fewer winding reworks. The surface finish of the insulation allows for tight slot fills while maintaining heat dissipation gaps, optimizing both electrical and thermal motor performance.

Longevity and Lifecycle Cost Savings

In cost-sensitive and performance-critical applications, the total cost of ownership matters more than the initial component price. PVC insulated winding wires deliver value by significantly reducing failure rates, unplanned downtime and maintenance needs.

When properly designed and applied, these wires can extend submersible motor life by years, even under demanding operational conditions. Reduced rewinding frequency means fewer service interruptions, less equipment handling and improved reliability of water delivery systems.

The initial investment in PVC insulated aluminium cable options pays off in long-term durability, reduced electricity consumption and enhanced motor output – especially when integrated into industrial-grade or high-volume submersible systems.

Conclusion

PVC insulated winding wires represent a critical advancement in the performance and reliability of submersible pump motors. By offering a blend of moisture resistance, thermal endurance, mechanical strength and chemical stability, these wires ensure that motors continue operating efficiently and safely even in the most challenging environments.

Whether it’s through PVC sheathed power cable or advanced winding configurations, it provides the protective foundation needed for submerged operations. As demand grows for dependable water management systems, the importance of using high-quality, well-engineered winding wires cannot be overstated.

Table of Contents