Table of Contents

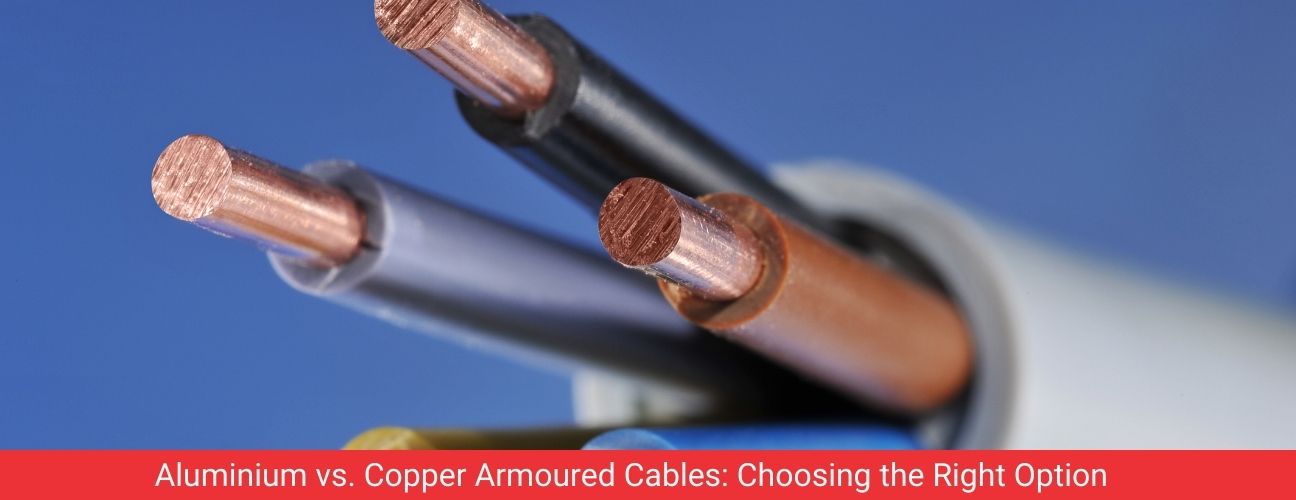

In the world of electrical engineering, the debate between Aluminium and Copper is rarely about which metal is “better”—it is about which is “better for the job.” While Copper offers superior conductivity, Aluminium offers unbeatable cost efficiency.

Knowing when to deploy each can save a project millions in material costs or prevent catastrophic failures in critical systems. Here is a guide to choosing the right armoured cable for specific project types.

Large-Scale Utility & Power Distribution Grids

Best Choice: Aluminium Armoured Cables

For government grids, substations, and long-distance power distribution, Aluminium is the undisputed standard.

- Why? In projects requiring kilometers of cabling, the cost difference is massive. Aluminium is approx. 60-70% cheaper than copper by volume.

- Application:

- Underground Main Feeds: connecting substations to local transformers.

- Street Lighting Networks: Long runs where voltage drop can be managed by upsizing the cable without breaking the budget.

- Overhead Lines: Aluminium’s lighter weight (30% of copper) reduces the structural load on pylons and poles.

Read Our Article: Different Core Aluminum Armoured Cables – An Overview

Heavy Industrial Plants & Manufacturing Units

Best Choice: Copper Armoured Cables

Factories with heavy machinery, motors, and high-vibration environments demand the robustness of Copper.

- Why? Copper has higher tensile strength and resists “creep” (loosening of connections under thermal cycling) better than aluminium.

- Application:

- Motor Connections: Connecting heavy 3-phase motors where vibration is constant.

- Control Panels: Tight spaces in MCC (Motor Control Centers) panels require thinner cables; Copper’s smaller diameter (for the same amp rating) makes it the only viable option.

- Crane & Hoist Wiring: Where flexibility and resistance to movement fatigue are critical.

Our Other Cables: Aluminium Armoured Cable (1.1KV 4 Core)

Commercial High-Rises & Residential Towers

Best Choice: Hybrid Approach (Aluminium for Mains, Copper for Distribution)

Modern building projects often use a smart mix of both to optimize costs without compromising safety.

The Strategy:

- Use Aluminium for the “Backbone”: Large Aluminium Armoured Cables are used for the main risers bringing power from the basement transformer to the floor distribution boards. These cables are static, thick, and offer huge savings.

- Use Copper for the “Final Mile”: From the floor distribution board to individual apartments or offices, Copper Armoured Cables are used. They are easier to terminate in standard wall sockets and handle the “stop-start” load of household appliances better.

Solar Farms & Renewable Energy Projects

Best Choice: Aluminium Armoured Cables (DC Main Lines)

Solar parks are essentially massive fields of “distance.” The primary challenge is reducing the cost of running cables over hundreds of acres.

Why? To minimize power loss over long distances, cables must be upsized. Upsizing Copper is prohibitively expensive. Upsizing Aluminium is cheap and effective.

Application:

- DC Collection Systems: Connecting combiner boxes to the central inverter.

- AC Output Lines: Transmitting power from the inverter to the grid substation.

Client Speaks

Guys it’s really good quality of cables…..

I am also using. So why are you wating🧐

Order Now………

Data Centers & Critical IT Infrastructure

Best Choice: Copper Armoured Cables

In projects where uptime is the only metric that matters—like Google, Amazon, or Banking Data Centers—Copper is king.

Why? Reliability and thermal efficiency. Copper runs cooler than aluminium for the same current, reducing the heat load on air conditioning systems. It also has lower oxidation risks, ensuring that critical server connections never fail due to a loose neutral.

Application:

- Server Rack Power Supply: delivering power to PDUs.

- UPS Systems: Connecting battery banks to critical loads.

Mining & Hazardous Area Projects

Best Choice: Copper Armoured Cables

Mines and oil refineries are hostile environments. Space is often restricted, and safety regulations are strict.

Why? In hazardous zones (ATEX environments), the risk of sparking from a loose aluminium oxide connection is unacceptable. Copper’s superior ductility and corrosion resistance make it the safer choice for explosion-proof installations.

Application:

- Underground Tunnel Wiring: Where cable damage is likely, and repairs are difficult.

- Oil Rig Platforms: Where salt spray corrosion would rapidly destroy exposed aluminium connections.

Read Our Article: Choosing the Right Aluminium Armoured Cable: A Comprehensive Guide

Project Decision Matrix: A Quick Summary

Project Type | Recommended Cable | Primary Reason |

Utility / Long Distance | Aluminium | Cost & Weight Savings |

Heavy Factory / Motors | Copper | Vibration Resistance & Size |

High-Rise Main Riser | Aluminium | Cost Efficiency for heavy loads |

High-Rise Floor Wiring | Copper | Ease of termination & flexibility |

Solar / Wind Farms | Aluminium | Long runs require cheaper upsizing |

Data Centers | Copper | Reliability & Heat Management |

Hazardous Areas (Mines) | Copper | Safety & Corrosion Resistance |

Conclusion: Making the Strategic Choice

In the final analysis, the debate between Aluminium and Copper Armoured Cables is not a question of quality, but of application. Neither metal is universally superior; rather, each dominates its own specific territory.

For infrastructure, long-distance transmission, and budget-sensitive projects, Aluminium is the clear winner, offering reliable performance at a fraction of the cost. However, for critical systems, hazardous environments, and heavy industrial machinery where failure is not an option, Copper remains the irreplaceable gold standard.

Smart engineering is about allocating resources where they matter most. By understanding the specific demands of your project—whether it is the vibration of a factory floor or the vast expanse of a solar farm—you can choose the cable that doesn’t just “work,” but delivers the best balance of safety, efficiency, and ROI.

Table of Contents