Table of Contents

Objective:

This article aims to provide a detailed roadmap for project managers and electrical engineers to navigate the complexities of selecting aluminum armored cables. By exploring the functional differences between various core configurations and the importance of cross-sectional area selection, this guide ensures that readers can optimize their electrical infrastructure for safety, cost-effectiveness and long-term durability.

Choosing the right wiring solution for industrial or commercial projects is a decision that balances electrical load requirements, environmental conditions and budgetary constraints. Aluminum armored cables have emerged as a preferred choice in modern infrastructure due to their lightweight nature and excellent conductivity-to-weight ratio. Unlike unarmored alternatives, armored cables feature a protective layer – typically steel wire or tape – that guards the internal conductors against mechanical damage, moisture and chemical exposure. Understanding the nuances of core counts and sizing is essential for ensuring the stability of a power distribution system.

1 Core Aluminium Armoured Cables and Its Specialized Applications

In high-current power distribution systems, 1 core Aluminium Armoured Cables play a pivotal role. Unlike multi-core variants, single-core cables are often used in AC systems where the absence of other phases within the same sheath helps manage heat dissipation more effectively. Because these cables carry only one phase, they are highly flexible in terms of routing within large industrial plants. However, engineers must be mindful of the magnetic fields generated; typically, single-core cables use non-magnetic armor, such as aluminum wire armor, to prevent the “eddy current” effect that can lead to overheating in steel-armored options.

2 Core Aluminium Armoured Cables for Single-Phase Systems

When dealing with single-phase residential or light commercial installations, 2 Core Aluminium Armoured Cables are the standard choice. These cables consist of a phase (live) and a neutral conductor. They are frequently utilized for street lighting, small machinery and peripheral power outposts. The armor provides the necessary ruggedness for direct burial in the ground or mounting on external walls, where protection from rodents or accidental impact is a priority. Choosing this configuration simplifies the installation process for systems that do not require a three-phase power supply.

3 Core Aluminium Armoured Cables in Balanced Industrial Loads

For three-phase AC power distribution where a neutral is not required – such as in certain motor drives or balanced industrial heaters – 3 Core Aluminium Armoured Cables offer an efficient solution. These cables house three insulated conductors, representing the three phases of the electrical supply. The symmetry of the three-core design helps in maintaining electromagnetic balance. When selecting this type of cable, the focus shifts toward the insulation quality, often involving materials like Cross-Linked Polyethylene (XLPE), which allows the cable to operate at higher temperatures compared to standard PVC, thereby increasing its current-carrying capacity.

3.5 Core Aluminium Armoured Cables for Unbalanced Power Distribution

In many real-world three-phase systems, the loads across the phases are not perfectly balanced, leading to a current flow through the neutral wire. This is where 3.5 Core Aluminium Armoured Cables become essential. In this configuration, the three main phase conductors have a full cross-sectional area, while the fourth “half-core” acts as the neutral and has a reduced area. This design is a cost-effective compromise for systems where the neutral current is expected to be significantly lower than the phase currents, allowing for a reduction in both material weight and overall project expenditure without compromising safety.

4 Core Aluminium Armoured Cables for Comprehensive Electrical Logic

When a project demands a full-sized neutral – often necessary in systems with high harmonic distortion or highly unbalanced loads – 4 Core Aluminium Armoured Cables are the gold standard. These cables provide four conductors of equal cross-sectional area. This ensures that the neutral conductor can handle the same level of current as the phases, which is a critical safety requirement in modern office buildings or data centers filled with non-linear electronic loads. Utilizing a four-core setup provides the highest level of versatility for future-proofing an electrical grid.

LT XLPE / PVC Aluminum Cable Price and Material Considerations

The longevity of an installation often depends on the outer sheath and internal insulation. When evaluating LT XLPE / PVC Aluminum Cable Price factors, one must consider the environment. XLPE insulation is preferred for its superior thermal properties and resistance to moisture, while PVC is often chosen for its flexibility and flame-retardant properties in less demanding environments. While the initial procurement cost might vary between these materials, the long-term reliability and lower maintenance requirements of XLPE often make it the more sustainable choice for large-scale infrastructure projects.

Our Other Cables: 1.1Kv Aluminium 3.5 Core (Armoured) Cable

Aluminium Armoured Power Cable: Factors and Market Dynamics

Understanding the broader Aluminium Armoured Power Cable Price landscape requires an analysis of global metal markets and manufacturing standards. Aluminum prices are generally more stable and lower than copper, making these cables an attractive option for long-distance power transmission. However, the complexity of the armoring process – whether using galvanized steel wire or tape – also influences the final cost. Investors and contractors must look beyond the initial tag and consider the total cost of ownership, including the ease of installation provided by the lighter aluminum conductor.

Testimonials

Guys it’s really good quality of cables…..

I am also using. So why are you wating🧐

Order Now………

1.1KV 4 Core Aluminum Cable Price per meter for Low Voltage Projects

For most low-voltage distribution tasks, the 1.1KV 4 Core Aluminum Cable Price per meter is a standard metric used for budgeting. This voltage rating is suitable for the vast majority of commercial and industrial internal power grids. Choosing a four-core configuration at this voltage level ensures that the system can support both three-phase machinery and single-phase lighting or office equipment simultaneously. The “per meter” calculation allows project managers to scale their procurement accurately based on site surveys and blueprint measurements.

1.5 sq mm Aluminium Armoured Cable for Control and Signaling

Small-scale applications require precision rather than bulk power. The 1.5 sq mm Aluminium Armoured Cable Price is often a consideration for control circuits, signaling and low-power lighting. Even at this small diameter, the addition of armoring is vital if the cables are to be laid in trenches or exposed to potential mechanical stress. It is important to ensure that even small-gauge cables adhere to strict conductivity standards to prevent voltage drops over long distances.

Read Our Article: How to Choose Different Armoured Cables in Different Applications

4 sq mm Aluminium Armoured Cable for Secondary Power Distribution

Moving up the scale, the 4 sq mm Aluminium Armoured Cable Price reflects a cable size commonly used for residential sub-panels or larger domestic appliances. This size provides a balance between flexibility and power capacity. When installing these cables, the armoring serves as a secondary ground in some jurisdictions, though a dedicated earth core is always recommended for maximum safety.

6 sq mm Aluminium Armoured Cable Price for Small Industrial Machinery

For workshops or small industrial units, the 6 sq mm Aluminium Armoured Cable cost is a frequent point of inquiry. This size is capable of handling the starting currents of smaller motors and industrial fans. The choice of aluminum at this size begins to show significant weight savings over copper, making it easier for technicians to pull the cable through conduits or secure it to cable trays.

10 sq mm Aluminium Armoured Cable: Price and Efficiency

The 10 sq mm Aluminium Armoured Cable represents a transition into medium-duty power delivery. It is often used for connecting outbuildings or powering heavy-duty HVAC systems. At this thickness, the mechanical strength of the aluminum conductor is substantial and the armoring must be robust enough to handle the potential external pressures of industrial environments.

16 sq mm Aluminium Armoured Cable Price for Commercial Feeders

In commercial construction, the 16 sq mm Aluminium Armoured Cable is relevant for sub-main feeders. This size can comfortably carry significant current for floor-level distribution boards. Engineers often specify this size because it offers a reliable safety margin for standard commercial loads while remaining cost-effective for large-quantity orders.

25 sq mm Aluminium Armoured Cable Price for Industrial Grid Extensions

As we move into larger gauges, the 25 sq mm Aluminium Armoured Cable cost becomes a factor for industrial grid extensions. At 25 sq mm, the cable is thick enough to handle substantial power but still manageable for manual installation. This is frequently the size where the benefits of aluminum’s lower weight become clearly visible during the labor-intensive process of laying kilometers of cable.

35 sq mm Aluminium Cable and Its High-Capacity Needs

When selecting based on the 35 sq mm Aluminium Cable Price, you are looking at a product designed for heavy-duty feeders. These cables are often used in manufacturing plants where large machines operate continuously. The thermal stability of the insulation becomes paramount here, as the heat generated by the resistance in the aluminum must be dissipated efficiently to prevent degradation.

Our Other Cables: Copper Armoured Cable / Copper Unarmoured Cable (1.1KV Copper Annealed)

50 sq mm Aluminium Armoured Cable: Procurement Strategies

In large-scale infrastructure, the 50 sq mm Aluminium Armoured Cable Rate is a key figure for procurement departments. This size is commonly used for main power entries in medium-sized buildings. Because of the volume of material involved, the rate is often negotiated based on the total project length, emphasizing the importance of accurate technical specifications before entering the bidding phase.

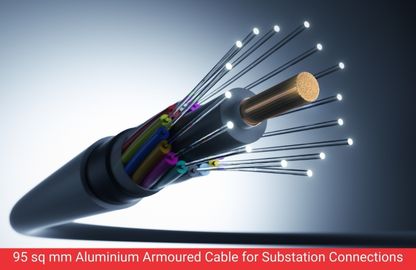

95 sq mm Aluminium Armoured Cable for Substation Connections

The 95 sq mm Aluminium Armoured Cable Price is a critical consideration for utility companies and heavy industry. This size is typically used for connecting secondary substations to main distribution panels. The armor on these cables is exceptionally thick to protect the high-voltage throughput from external environmental hazards, ensuring a steady flow of electricity to thousands of downstream users.

120 sq mm Aluminum Cable Cost and Scale of Investment

At the level of the 120 sq mm Aluminum Cable Cost, we are discussing significant infrastructure investment. These cables are designed for high-ampere loads and are staple components in the expansion of urban power grids. The choice of aluminum here is almost mandatory for overhead or long-distance underground runs due to the prohibitive weight and cost of copper at similar scales.

185 sq mm Aluminium Armoured Cable for Primary Power Links

Primary power links between large industrial sectors often rely on the 185 sq mm Aluminium Armoured Cable Price for their feasibility studies. These massive cables require specialized equipment for installation, including heavy-duty rollers and tensioning devices. The integrity of the armor is tested rigorously, as any breach at this power level could result in significant downtime and safety risks.

Read Our Article: Choosing the Right Aluminium Armoured Cable: A Comprehensive Guide

240 sq mm Aluminium Armoured Cable for Metropolitan Infrastructure

Urban centers with high density require massive energy throughput, making the 240 sq mm Aluminium Armoured Cable Price a vital metric for city planning. These cables feed high-rise buildings and transit systems. The engineering focus here is on reducing transmission losses, which is achieved through high-purity aluminum conductors and precision-engineered insulation layers.

300 sq mm Aluminium Armoured Cable Price and Large-Scale Distribution

The 300 sq mm Aluminium Armoured Cable is relevant for the heavy hitters of the electrical world. Used in power plants and massive smelting facilities, these cables are the arteries of the industrial body. Every millimeter of thickness is calculated to ensure that the voltage drop is kept to an absolute minimum, maximizing the efficiency of the entire electrical system.

400 sq mm Aluminium Armoured Cable Price for Specialized High-Power Zones

In specialized zones, such as mining operations or large chemical plants, the 400 sq mm Aluminium Armoured Cable reflects the extreme requirements of the environment. These cables are built to withstand not just mechanical pressure, but also potential chemical seepage. The aluminum conductors are often treated or bundled in specific configurations to enhance their flexibility despite their massive size.

Our Other Cables: Aluminium Armoured Cable (1.1KV 4 Core)

500 sq mm Aluminium Armoured Cable Price for National Grid Integration

Connecting localized grids to national systems often involves the 500 sq mm Aluminium Armoured Cable. These are among the largest standard cables used in underground distribution. They provide the necessary “bandwidth” for electricity, ensuring that peak demand periods do not stress the physical infrastructure to the point of failure.

630 sq mm Aluminium Armoured Cable: The Future of Energy

As renewable energy plants, like solar and wind farms, increase in size, the 630 sq mm Aluminium Armoured Cable Price becomes a focal point for green energy developers. These cables carry the bulk energy generated from remote locations to the main grid. Their durability in outdoor, often harsh environments is a testament to modern engineering.

800 sq mm Aluminium Armoured Cable Price for Mega-Projects

For mega-projects, such as international airports or massive industrial complexes, the 800 sq mm Aluminium Armoured Cable Cost is a necessary expenditure. These cables handle currents that would melt smaller wires instantly. The armoring here is not just for protection, but also adds structural rigidity to the cable as it traverses complex underground duct banks.

1000 sq mm Aluminium Armoured Cable for Extreme Industrial Loading

The 1000 sq mm Aluminium Armoured Cable Price marks the entry into custom-engineered territory. At this size, cables are often made to order, with specific requirements for the armor and outer sheath. These are used in the most power-intensive environments on earth, where a single cable failure could cost millions in lost production.

1500 sq mm Aluminium Armoured Cable: Heavy Power Transmission

Finally, the 1500 sq mm Aluminium Armoured Cable Price represents the pinnacle of aluminum cable engineering. These cables are used in heavy power transmission where enormous quantities of electricity must be moved safely. Despite their size, the use of aluminum keeps them relatively light compared to copper, allowing for easier handling during the complex installation processes required for such large-scale components.

Conclusion:

Choosing the right core and size – from a small 1.5 sq mm control wire to a massive 1500 sq mm transmission cable – requires a deep understanding of your project’s specific electrical load and environmental challenges. By selecting the appropriate core configuration and cross-sectional area, you ensure a safe, efficient and cost-effective power distribution network.

Table of Contents