Table of Contents

Objective:

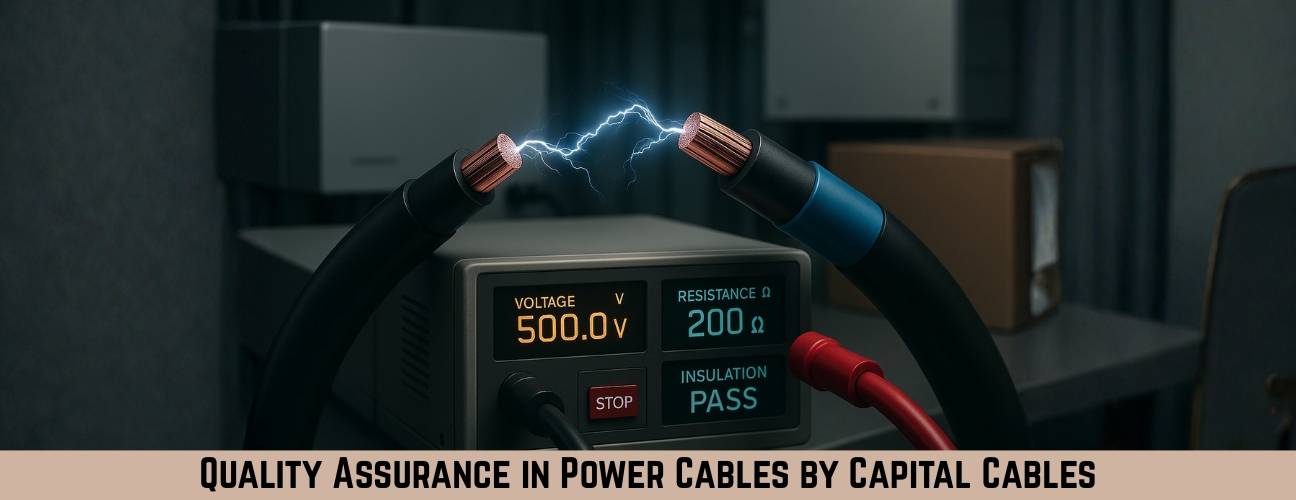

The goal of this article is to provide a comprehensive understanding of the testing standards for power cables, focusing on Capital Cables and its commitment to ensuring the highest quality. As a leading power cables manufacturer, Capital Cables adheres to stringent testing protocols to ensure that every product – whether industrial power cables – meets the highest safety and performance standards. This article will explore the critical tests conducted on power cables and why these standards are vital in the production of reliable and safe electrical infrastructure.

Introduction: The Importance of Testing Standards for Power Cables

Power cables are integral to the smooth and safe transmission of electricity across various applications. Whether it’s for residential, commercial or industrial use, the quality and reliability of these cables are paramount. Ensuring that power cables meet rigorous testing standards is crucial for their long-term performance and safety.

Capital Cables, as a leading power cables manufacturer, recognizes the importance of adhering to global testing standards for all of its products, including power cables for electrical wiring. These cables are subject to a series of stringent tests that assess their ability to perform under varying conditions and environments. This article delves into the critical testing standards that ensure the safety and reliability of power cables and highlights Capital Cables’ commitment to maintaining excellence in quality control.

Testing Standards for Power Cables: A Comprehensive Overview

1. Electrical Performance Testing

One of the most critical aspects of power cable testing is evaluating their electrical performance. This includes testing for conductivity, insulation resistance and the ability to withstand high voltage without breakdown.

- Conductor Resistance Test: This test measures the resistance of the conductors (typically copper or aluminum) in the cable. A low resistance is essential for efficient electricity transmission. Power cables with high resistance can lead to energy losses and excessive heat generation.

- Insulation Resistance Test: Insulation is crucial for preventing electrical faults, such as short circuits. This test ensures that the insulation material used in insulated power cables provides sufficient resistance to electrical current and prevents leakage.

- High Voltage Testing: Cables are subjected to high voltage to simulate real-world electrical stress. This ensures that power transmission cables, can handle voltage fluctuations without breaking down or causing electrical hazards.

Capital Cables ensures that all of its cables pass these electrical performance tests, meeting the required standards for safe and efficient power transmission.

2. Mechanical Stress and Durability Testing

Power cables must withstand mechanical stresses such as bending, stretching and pulling, especially in industrial environments or underground installations. The durability of the cables is tested through various methods to ensure they can handle these stresses without compromising their performance.

- Tensile Strength Test: This test measures how much weight or force the cable can withstand before the conductors or insulation material start to fail. Industrial power cables, especially those designed for heavy-duty applications, must pass tensile strength tests to ensure they perform under harsh conditions.

- Impact and Abrasion Resistance: Power cables often encounter physical wear due to installation processes or exposure to mechanical forces. These tests evaluate how well cables can endure impacts, abrasions and crushing forces, ensuring their reliability over time.

- Bend Test: Cables, especially underground power cables, must be flexible enough to navigate corners or bends without damaging the internal components. The bend test ensures that the cable can be installed without compromising its integrity or performance.

Capital Cables places a strong emphasis on these mechanical tests to ensure that their industrial copper power cables and other products maintain their reliability even in the most demanding environments.

3. Thermal and Fire Resistance Testing

Cables must be able to withstand high temperatures without losing their functionality or safety features. This is particularly important for cables used in high-tension applications or for electrical wiring in areas exposed to heat, such as industrial plants or power substations.

- Temperature Cycle Test: This test involves subjecting cables to extreme temperature changes to simulate real-world conditions. Power cables must remain operational without degradation, even after repeated cycles of heating and cooling.

- Fire Resistance Test: Power cables must also be fire-resistant to prevent the spread of flames in the event of an electrical fault. Cables, particularly those used in residential or commercial buildings, need to meet fire resistance standards to ensure the safety of the surrounding infrastructure.

Capital Cables ensures that its power cables for electrical wiring pass rigorous fire resistance and temperature cycle tests, adhering to both local and international safety regulations.

4. Environmental Resistance and Ageing Testing

Power cables are exposed to a variety of environmental conditions, including moisture, UV radiation and chemical exposure. To ensure they can function reliably in these environments, various environmental tests are conducted:

- UV Resistance Test: Cables exposed to sunlight or harsh outdoor conditions must be resistant to UV degradation, which can weaken the insulation material and reduce the cable’s lifespan.

- Moisture and Water Resistance Test: In applications where cables are used in damp or submerged environments, such as underground power cables, it is crucial that they resist water ingress. Cables are tested for moisture resistance to ensure they remain functional and safe even in water-prone areas.

- Chemical Resistance Test: In industrial settings, cables may come into contact with corrosive chemicals or other harsh substances. Testing ensures that the cables can resist chemical damage without compromising safety.

These tests are particularly important for cables used in industries such as manufacturing, oil and gas and construction. Capital Cables ensures that its products are fully tested for environmental resistance, including moisture and UV stability, ensuring long-lasting durability in diverse environments.

Testimonials

“Guys it’s really good quality of cables…..

I am also using. So why are you wating

Order Now………”

5. Compliance with International Standards

To ensure that their power cables meet global requirements, Capital Cables adheres to internationally recognized standards and certifications. These include:

- IEC Standards (International Electrotechnical Commission): These standards outline the requirements for the design, testing and performance of power cables used in various applications.

- BS Standards (British Standards): Specifically for European markets, these standards regulate the safety, performance and quality of power cables in commercial and industrial settings.

By adhering to these internationally recognized standards, Capital Cables guarantees that its industrial power cables and other products are suitable for use in a wide range of global markets, meeting the highest safety and quality benchmarks.

Conclusion:

Testing standards for power cables are crucial to ensuring the safety, reliability and longevity of electrical systems. Capital Cables understands the importance of stringent testing procedures and continually invests in advanced testing equipment and methodologies. By adhering to global standards and conducting comprehensive tests – ranging from electrical performance to environmental resistance – Capital Cables ensures that its power cables, including high tension power cables, industrial copper power cables and insulated power cables, are of the highest quality.

With a clear focus on maintaining quality, Capital Cables is committed to providing safe and reliable power cables that meet the needs of diverse industries. As the demand for advanced electrical infrastructure continues to grow, Capital Cables remains a trusted name in delivering innovative, high-performance power cables that adhere to the most stringent testing standards.

Table of Contents